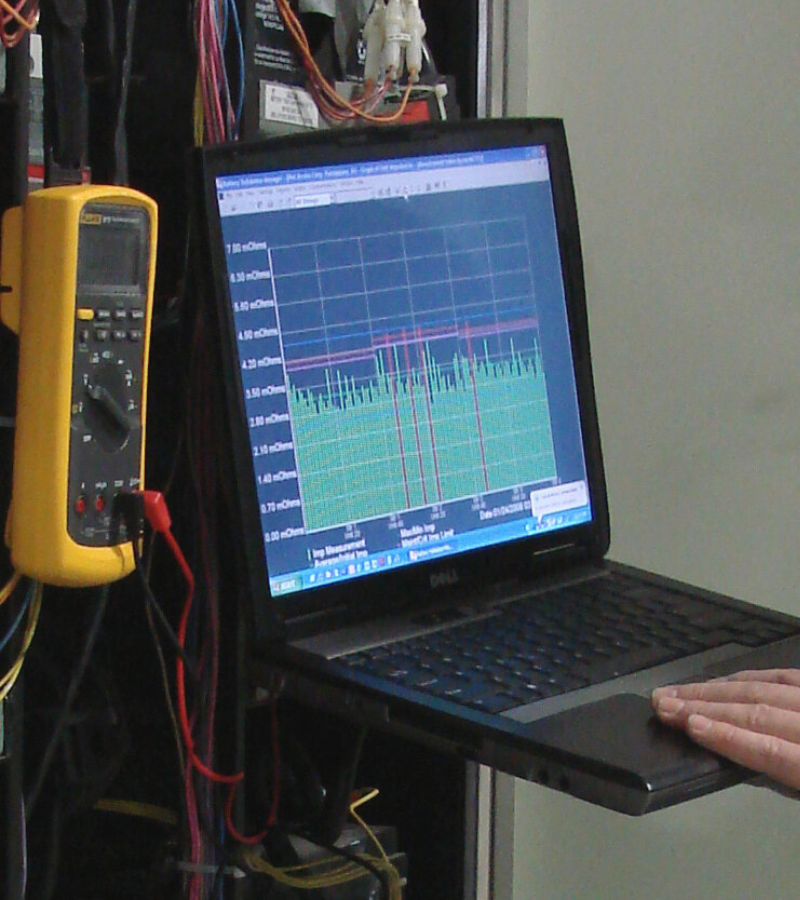

A specialized solution designed to detect ground faults in DC battery systems. The BGM-500 is a standalone product that doesn’t require custom software or programming to be integrated into Data Center Infrastructure Management (DCIM) or an existing building management system.

Over time, batteries can corrode and leak. If the leaking electrolyte makes contact with the metal cabinet or rack, it can short the battery to the cabinet or rack. The BGM-500 measures current that flows from the battery to earth ground. When the system spots a current above the configurable threshold value, it sends notifications about battery ground failures via SNMP, Modbus, an internal web server, on-board LED and alarm contacts.