As the world’s longest continuing battery monitoring company, BTECH has been shaping the industry for over three decades. We stay #1 because our finger is always on the pulse of cyber security, changing regulations, and product and business evolution.

We source components with supply chain expertise to build and ship systems as needed and secure quick lead times for our customers.

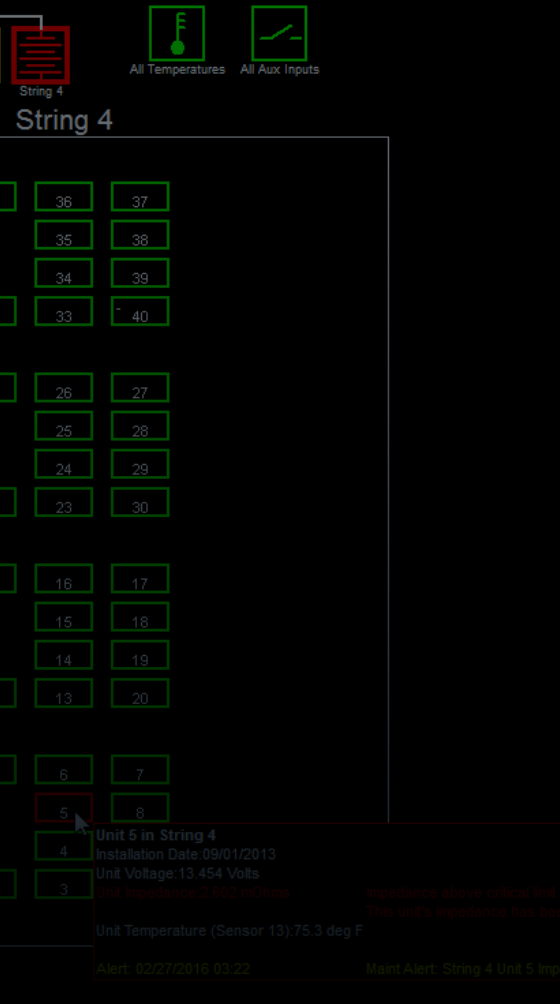

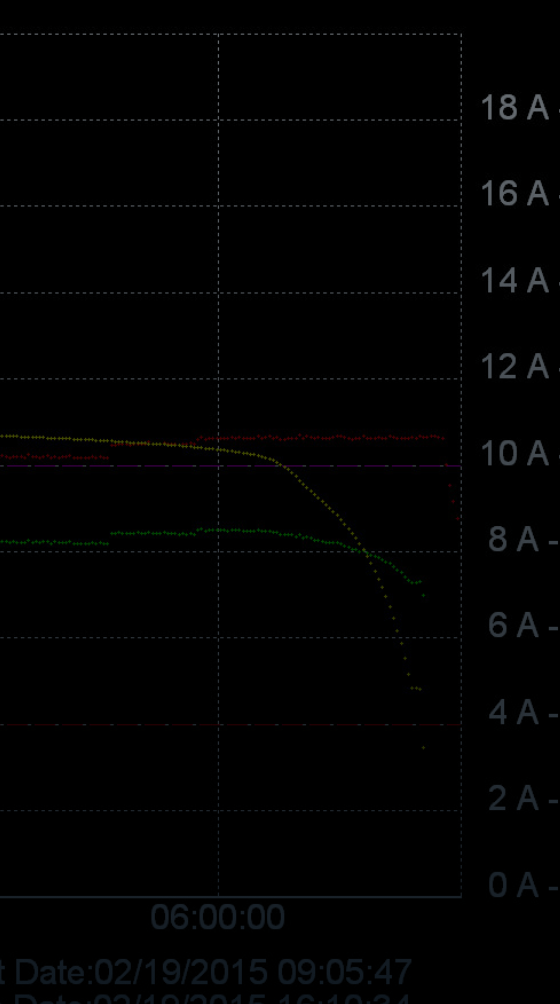

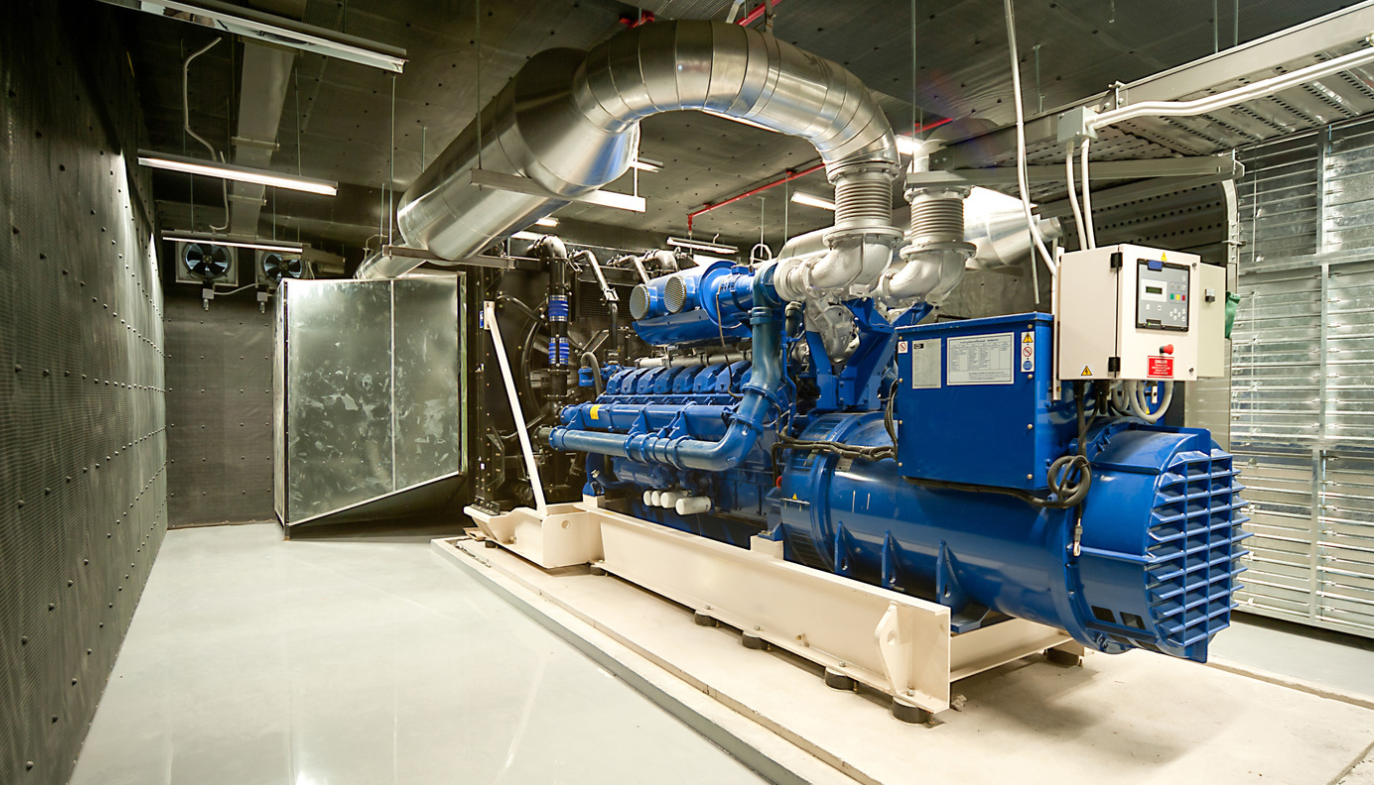

With over 10,000 systems deployed, we’ve mastered the design and production of intelligent battery validation technology that assures reliability, streamlines operational consistency, and optimizes the management of reserve power systems.